High-Throughput Assays

Accelerating Drug Development Process at Scale

Nexelis, a Q² Solutions Company, utilizes automated systems for high throughput through our investment in robotics to support our scientists, who generate over 1.5 million results annually. Our immense capacity helps accelerate the drug discovery and clinical trial process. Controlling for variability when performing manual processes at the order of magnitude required for large sample volume throughput is virtually impossible. However, our investment in automation helps our team to deliver consistently with accuracy, reproducibility, and precision to meet client’s expectations and timelines. Our automated, validated data reporting systems also ensure objectivity when generating results. With state-of-the-art equipment at our facilities globally, our team produces data for large scale projects with increased output for consistent and timely delivery of results.

High-Throughput Automation

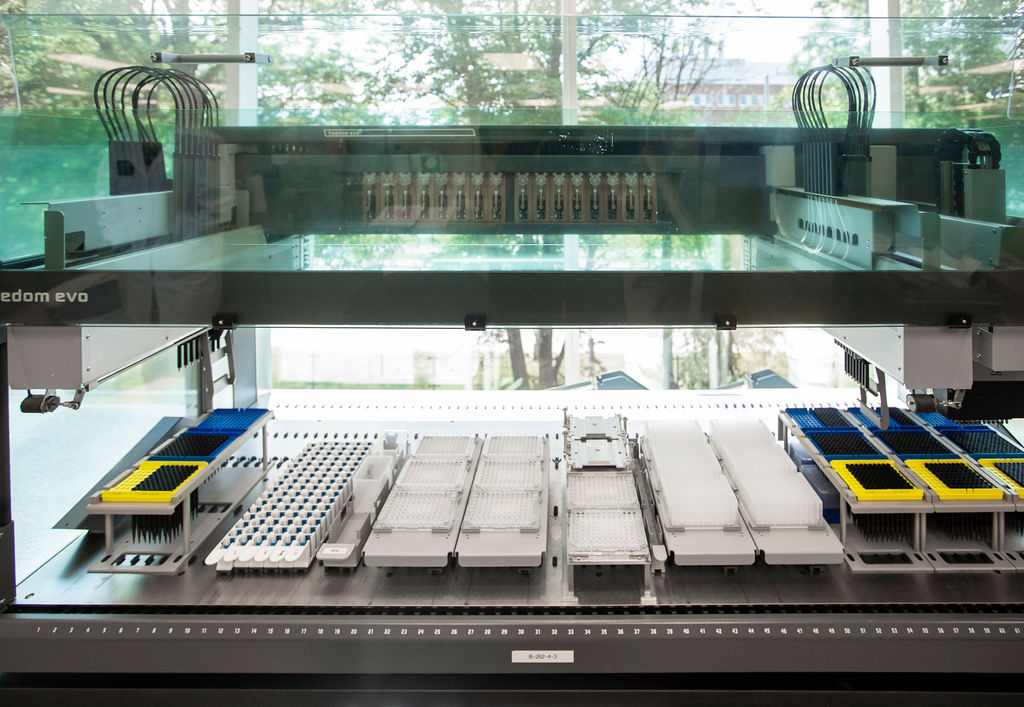

Robotics

Nexelis has invested in state-of-the-art automation platforms that allow in-house High Throughput Screening (HTS). With robotics to support our specialty lab testing platforms, our laboratories are integrated with industry leading turnkey solutions ranging from assay set up and execution to sample storage, including automated labeling. Robotic workstations have several advantages over manual processes as robots can work continuously to increase the throughput, perform consistently, and ensure accuracy and precision. With our ability to quickly scale-up operations, our teams are well-equipped to meet market demands without compromising the flexibility and agility we are known for.

Our robotic systems help to streamline the workflow of your projects and optimize laboratory capacity by maximizing how we utilize our bench space. Automation provides greater efficiency and reproducibility of assays without compromising the quality of our data. In addition of the ability to provide efficient and reliable results, the process (study set up, timelines, etc.) and the performance efficiency of our technicians has markedly improved. Replacing manual, repetitive tasks with automation allows our experts to focus on solving the key problems for our clients.

Automated Liquid Handlers

Our automatic liquid handlers can detect a broad range of immune markers in the serum, plasma, or cell culture supernatants. Automation has increased our testing capacity, as compared to manual experiments, particularly for pipetting operations. We can perform sample preparation, dilution, and plating and pressure-monitored pipetting. Our robotic liquid handling workstations can track barcodes and provide fully traceable results.

Equipment

- Roche COBAS e411, e801, c501

- TECAN EVO200

- Integra AssistPlus

- Integra ViaFlow

- Integra ViaFill

- PerkinElmer Janis Liquid Handler

- Scinomix Tube Labeler

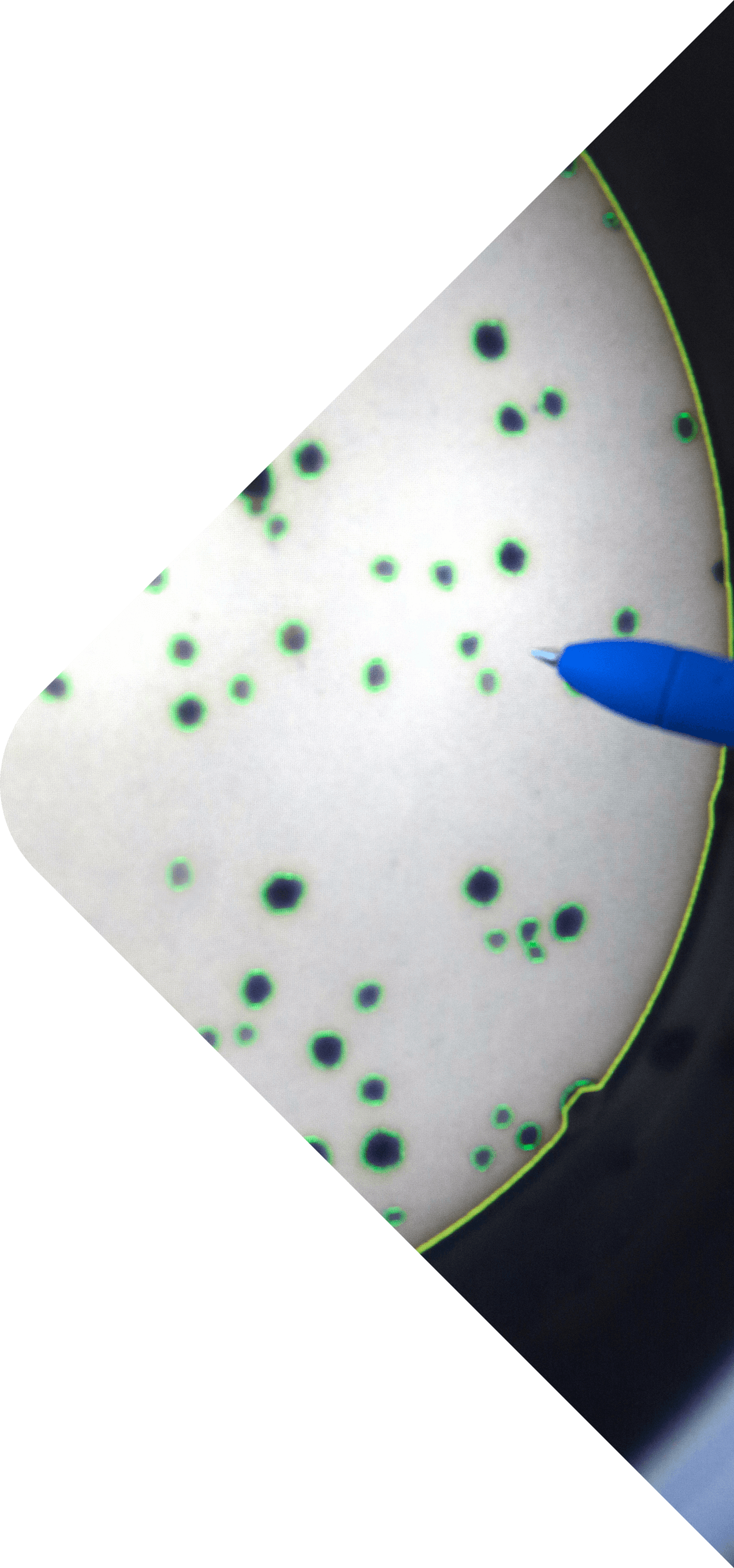

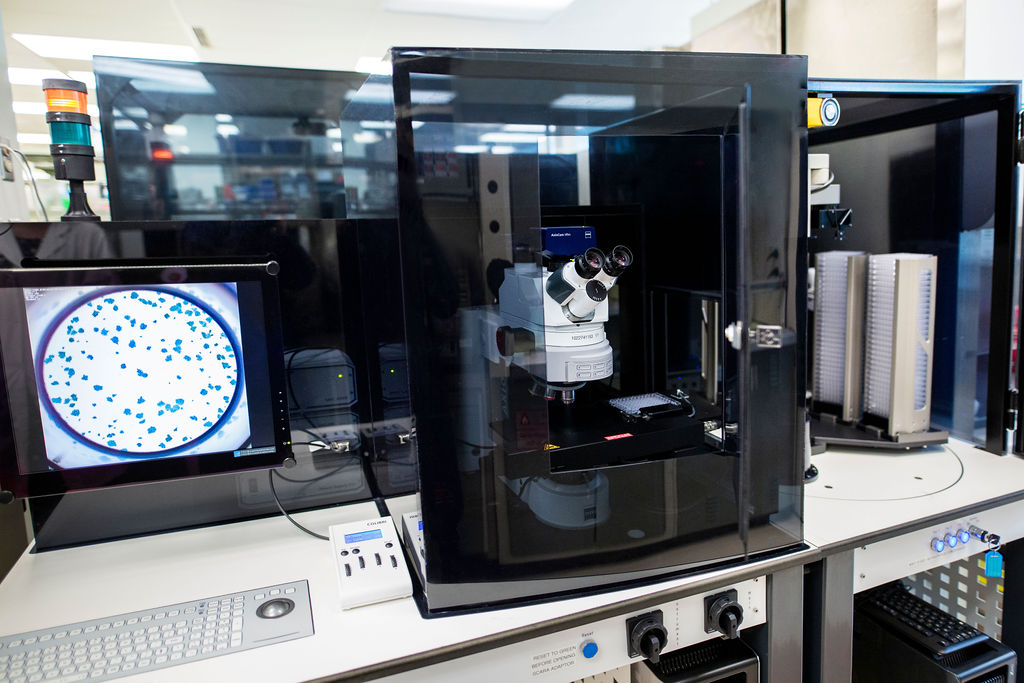

Automated Image Analyzers

Nexelis has a wide range of automated image capture and analysis systems to support viral and bacterial functional assays for the determination of plaque-forming-units (PFU) or colony-forming-units (CFU).

Microtechnix Axio Systems

- Automated inverted microscope and automated microscope

- Top-Bottom Image Analysis

InDevR CipherOne

- Image analysis system

- Automated hemagglutination (HA) and hemagglutination inhibition (HAI) interpretation instrument.

BioTek Cytation 7

- Cell imaging system with multiple reader modes combines an upright and inverted microscope and multimode multiplate detection.

Custom Validated Template for Data Capture and Analysis

Our data generation and repository include programing and validation using Excel and SoftMax Pro software. These software simplify your data acquisition and report workflows. Raw data can be imported directly from any of our assay instruments without loss of integrity, simplifying data acquisition and report workflow. Our integrated data analytics service also includes a convenient specialized calculation worksheet. Using input data collected from the assay instrument, the workbook will calculate the concentration of the analyte and report whether the concentration is reliable based on the standard curve. All data results generated within these templates sync automatically to our LIMS system.

Electronic Laboratory Notebook (ELN)

Integrating the ELN and LIMS with the laboratory equipment increases data exchange that drives consistent study execution which results in higher quality data within a shorter time frame than a paper-based laboratory.

Within our fully paperless laboratory in Indianapolis, manual transcription and processes are replaced with barcodes and business logic driven workflows. By eliminating the paper burden, the science is elevated to the highest priority.

Benefits of our ELN system:

- Increases data accessibility.

- Removes paper documentation burden.

- Eliminates human calculation errors.

- Is adaptable to new science and regulations

- Enforces compliance with SOP and processes that reduces deviations.

- Reduces rework.

- Performs virtual quality control checks.

- Allows for more efficient use of Quality Assurance (QA) resources.

- Allows for instant retrieval to archived studies during audits.